3 Easy Facts About Steel Fabrication Shown

Wiki Article

The Best Guide To Fabrication Steel Chart

Table of ContentsThe Of Steel FabricationAn Unbiased View of Fabricated Steel AngleSome Known Incorrect Statements About Steel Fabrication Industry The Facts About Steel Fabrication Process UncoveredThe Best Strategy To Use For Fabricated Steel AngleHow Fabricated Steel Angle can Save You Time, Stress, and Money.

In addition, it is much faster to scale mass production due to the versatility of construction alternatives. Since it is thin as well as has a light-weight kind element, any kind of added supply needed for manufacturing can be kept and transported conveniently. There are loads of methods to produce sheet steel depending on the application.Bending, Sheet metal is placed within a bending equipment and curved to the preferred shape. The most usual flexing machine is called a press brake. The brake makes use of a die and also hydraulic press to imprint the bend onto the metal. Typically utilized to form electronics enclosures. Marking, A sheet steel blank is placed right into a marking press where it is created right into the wanted shape utilizing a tool and pass away.

There are numerous cutting methods used, each of which uses unique attributes that make it ideal for various applications. The earliest method of reducing is sawing.

Not known Details About Fabrication Steel Chart

This process uses using a high-powered laser to cut materials to the desired sizes and shape. Contrasted to various other cutting procedures, it provides greater cutting precision and precision, especially for complicated as well as complex component layouts. Machining Machining is a subtractive procedure, meaning it creates parts as well as items by removing material from the workpiece.Two of the most typical CNC machining procedures are CNC milling as well as CNC turning - steel fabrication near me. CNC milling operations rely on rotating multi-point cutting tools to remove excess steel from a work surface. While the procedure is frequently utilized as a completing treatment, it can be made use of to complete an entire job. CNC turning operations utilize single-point cutting devices to remove material from the surface area of a rotating work surface.

Steel manufacture is all around you and you might not even understand it. Whether you're just interested in how points are made, how the market functions, or why metal manufacture is so essential, this article will detail it all.

Everything about Fabricated Steel Angle

They are located in the construction sector, service center, shipyards, landing fields, and also everywhere in between. Generally, they come from CNC factory as well as construction centers across the nation. Ever because the early days of the industrial transformation, CNC factory have actually gone to the center of development when it involves industrial modern technology, equipment, as well as automation.

Next time you drive your auto or notification something steel making your life an entire great deal easier, take a moment to believe of where it came from, as well as the numerous genuinely world-changing technological discoveries that have actually been made over hundreds of years to make it feasible. Do you require steel fabrication solutions? Baron Device does it all (steel fabrication industry).

All About Steel Fabrication And Welding

The process can be utilized in making mass-produced items or custom designs. Whether mass-produced or customized created, completion items are made with a wide variety of steels and also their alloysstainless steel, carbon steel, light weight aluminum, copper, brass to call a couple of. In commercial fabrication processes, opportunities are several of the adhering to approaches will be used to finish or produce a part or final product: Reducing The cutting of a steel work surface is a common construction strategy in which the material is split or cut into smaller sections.

The old days of sawing have actually been superseded by modern-day kinds of cutting that use modern machinery. From power devices to computer system mathematical computer (CNC) cutters, today's techniques consist of laser cutting, waterjet cutting, power scissors, as well as plasma arc cutting.

Strips or sheets of steel are continuously fed through parallel rollers that shape the work surface right into the desired form. During the procedure of forming, the steel material does not shed its mass, only its type. Punching Punch presses are mechanical gadgets or devices used to punch or develop openings in steels.

The Ultimate Guide To Steel Fabrication And Welding

In massive construction operations, commercial CNC set presses are utilized to produce complicated styles at higher result to meet both hefty and also light metalwork. Shearing Utilized to cut or remove unwanted material from metal material, shearing is accomplished by installing 2 blades over and also beneath the metal to create one long, straight cut.Straight cuts are attained by integrating 2 devices, basically blades, with one of the devices above the metal and the other one situated listed below for using Bonuses pressure. The upper blade compels the steel down onto the repaired or fixed reduced blade to fracture the piece as well as complete the splitting up. Stamping Similar to punching, marking develops an indentation rather than a hole throughout fabrication.

Metals can differ fit or size. The three primary kinds of welding procedures are Stick or Arc Welding, MIG Welding, and TIG Welding. Place welding and also stud welding are 2 other functional welding applications made use of in industrial steel manufacture shops.

Excitement About Steel Fabrication Apprenticeship

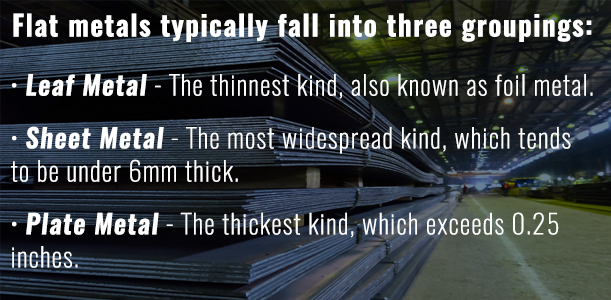

The tube laser cutter can reduce innovative patterns as well as holes on steel extrusions as well as tubes. Guillotine cutters are also made use of for straightforward cuts or materials that ought to not be exposed to the laser's higher temperatures.Laser cutters usage high-power laser beams to thaw the steel. High-pressure gas (nitrogen, air, or carbon dioxide)is made use of to blow the molten steel out and complete the cut. g. powder coating)can be utilized prior to or after the assembly to settle the metal manufacture process. Premium metal manufacture does not rely just on the high quality of the equipments and also procedures. Having a skilled team is one of the most important Read Full Article variable to ensure the finest of the offered metal fabrication services. We have a devoted metal fabrication group at Westberg Sheet Steel. You can likewise join the production team of Ultralift Australia. Ultralift provides custom steel and aluminium items for the AV sector. If you wish to utilize a much more exact K-factor, instead of utilize this graph, you'll require around 3-5 examination pieces to gather some details, consisting of bend allowance (BACHELOR'S DEGREE), bend distance(Ir)as well as material density (Mt). Extra detailed details on determining the K-factor can be found in this article. Below are a few of the different kinds of steel construction: In this kind of steel construction, molten steel is poured right into a mold or die, permitting it to cool down off. It then starts setting right into the designated shape, making the procedure sensible for mass-producing identical products. There are various kinds of casting. The worker uses stress to make sure it remains in area until it sets. An additional kind of casting is semi-permanent mold casting, where the molten metal is put right into mold and mildews with expendable cores, making original site them simpler as well as cheaper to get rid of. Cutting is a typical fabrication type that involves slicing a metal workpiece to separate it right into smaller sized sections. Like attracting, this procedure can be carried out with steel heated well above space temperature level to simply under recrystallization temperature, called warm forging.Once the temperature level gets to recrystallization degrees, it is then called hot building. It is one of the earliest types of metal fabrication, with the very first blacksmiths utilizing forging to work with steel.

Report this wiki page